Overview

Toyota is a well known company, has many operational procedures that participate in improve the production and increase the ability for the company in provide high quality cars with economic price, therefore it enter most world market even US market the first enemy !

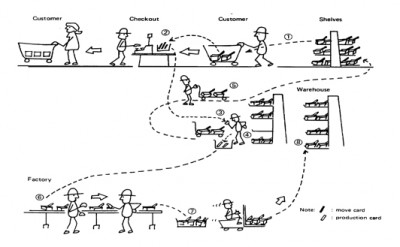

Back to 1940 Toyota improve its engineering process in production through apply the idea of the quantity of supermarket shelves.

Therefore there is always a relation between the customer consume quantity for specific item and quantity on the shelves. As every time the customer withdraw items from the shelves and pay on supermarket cashier through item sticker (Kanban in Japanese), thus after sell a specific amount of the same item, an import request is created for super market inventory for the same item, then when the item reach to specific amount an import request created to the vendor and so on. However there is a relation between consume and import amount.

However in this way the consumer is the main driver for inventory and all the operation, therefore this not required too much inventory time. Toyota apply the same idea in its production lines by connect team capacity with work load and this what is known as PULL SYSTEM.

Therefore through kanban ticket Toyota apply it on production line between the work teams. For example the door designer team withdrew work load according to their capacity and focus to deliver the work load, then after they deliver the work they notify the designer team for example to load another work load and so on. However this is the same idea of super market shelves but it replace the customer with team and items with work load.

Thus Kanban is doing the same idea in software development also, therefore the ability for the development team to deliver a specific amount of work load, thus make the team more flexibility in planning and fast output through development cycle.

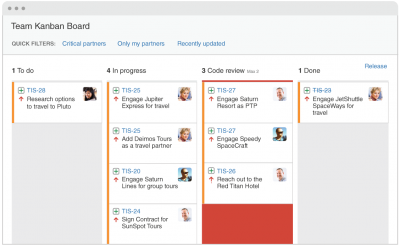

Kanban in Software Development Management

Kanban team focus on the current progress tasks, and after delivery the team load more tasks from the updated and prioritized backlog, therefore the product owner are free to prioritize the work without need to cut team work. However team are focus on the current work tasks, while be sure of the most business value for the product because Product Owner are always prioritize the tasks and product stories based on business value.

Estimation in Kanban

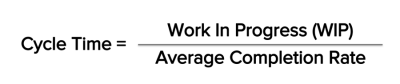

While the key metric in Scrum is Velocity the Kanban key metric is Cycle time, Cycle time is the time for the team to deliver work unit from start time until deliver it.

However the equation is simply consist of Work in Progress (WIP) and the average for completion rate, as below:

Scrum VS Kanban

| Kanban | Scrum | Compare |

|---|---|---|

| Continues flow | Flow within development sprints | Flow |

| Continuous delivery | At the end of each sprint if approved by the product owner | Release |

| No existing roles | Product Owner, Scrum Master, development team | Roles |

| Cycle Time | Velocity | Key Metric |

| Changes any time | Teams should strive to not make changes to the sprint forecast during the sprint. Doing so compromises learnings around estimation. | Changes |

To the next blog,

Best Wishes !

References

http://leankit.com/learn/kanban/what-is-kanban/

https://www.atlassian.com/agile/kanban

https://ar.wikipedia.org/wiki/%D9%83%D8%A7%D9%86%D8%A8%D8%A7%D9%86